Cavity Pressure Sensors

With PRIAMUS cavity pressure sensors the properties of an injection molding part are already monitored during production and adjusted if necessary.

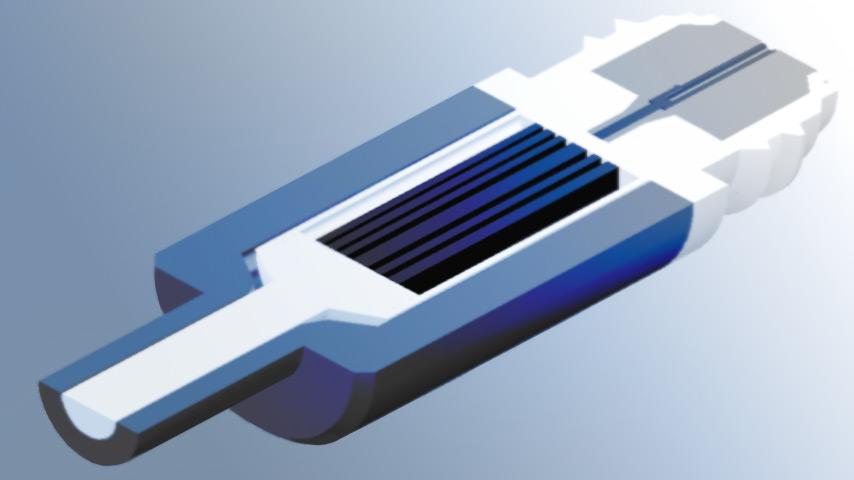

Cavity pressure sensors are active sensors, which means that neither power supply nor electronics are installed in their housing. This makes the sensor a real flyweight. Yet thanks to the right technology, they can easily withstand the high temperatures in the injection mold despite their small size and weight.

PRIAMUS cavity pressure sensors have separable connection cables that can be easily exchanged. In addition to angled connection cables, some sensors have hardened or machinable sensor fronts. Most sensors are equipped with PRIASED® sensitivity detection or PRIASAFE™ protective cover.

PRIASED® Automatic Sensitivity Detection

Plug & Measure - PRIASED® makes working with cavity pressure sensors child's play.

PRIASED® is a system for automatic sensitivity detection for cavity pressure sensors. Measurement data on sensor sensitivity are stored on a hardware code, which is permanently installed in the sensor housing.

PRIASED® offers the following advantages:

- Plug & Measure

Automatic assignment of the correct settings: The user does not need to worry about the correct sensitivity values of the sensors.

- Error reduction

Due to the automatic assignment there is no mix-up.

- Robust and temperature resistant

The hardware code can withstand high temperatures.

In recent years, the concept of automatic sensitivity detection has become widely accepted in process monitoring and closed-loop process control. Automation as required in the "IoT" (Internet of Things) environment is hardly conceivable from today's point of view with manual settings.

PRIASAFE™ Installation-safe Sensor with Protective Cover

Even the best sensor can be used in the wrong way!

Cavity pressure sensors are highly sensitive measuring instruments that deliver very precise results. The sensitive part of the sensor must stand freely in the bore and may not touch the bore wall. If this happens anyway, the sensor sensitivity is reduced due to the so-called «force shunt» and the measurement results are therefore incorrect.

PRIASAFE™ is a concept in which the sensor is surrounded by a protective cover. This protects the sensor from negative force effects due to incorrect installation and thus ensures correct measurement results.

Angled Connectors

Angled connectors - simple but effective!

Tight installation conditions? With our angled connectors you can save space where there is none.

Small sensors are required for tight installation conditions. Often, however, it is not the size of the sensor that causes the mold engineering headaches, but the question of where to place the connection cable.

Our answer: angled connectors!

Many of our cavity pressure sensors are available with angled connectors to lead the connection cable laterally outwards. Sensor modifications? Not necessary, because the connection cable can be separated from the sensor and thus be replaced at any time.