Products

Solution-focussed ‒ Modular ‒ Customer-oriented

Innovative products for specific requirements

The compatibility of our products is a major concern for us. Our sensor technology, connection technology, and hardware is modular and specially designed for a holistic process view. We collect pressure and temperature values in the mold and link these with other data from the injection molding machine and peripherals. With our solutions, we set quality standards in sensor technology, connection technology, and electronics.

Data acquisition and processing

Every injection molding process is different and requires its own tailor-made solution.

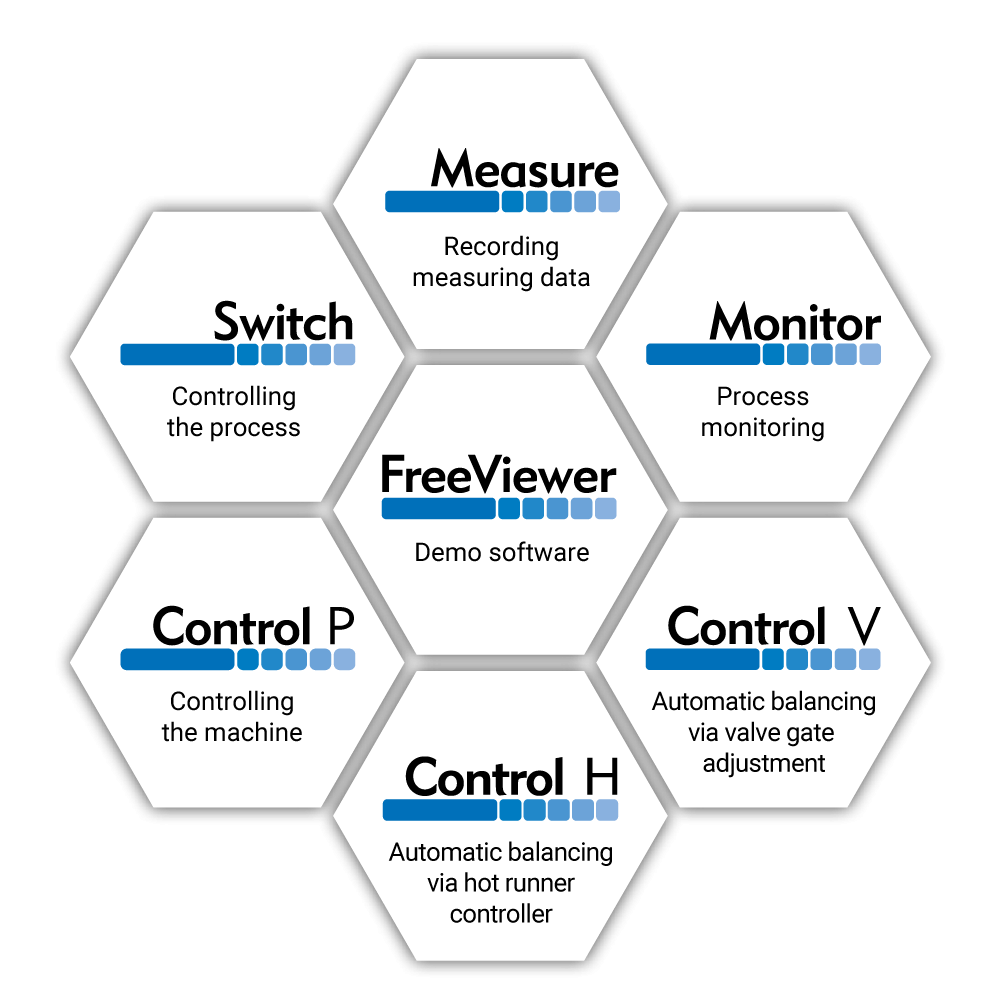

FILLCONTROL is the modular process monitoring system from PRIAMUS that can be flexibly adapted to individual customer requirements. Documenting, monitoring, open-loop or closed-loop process controlling – FILLCONTROL covers all applications with the appropriate module.

We create the data basis of FILLCONTROL by recording real process data within the mold. We are convinced that the data must be measured where the molding parts are actually produced – in the mold and not in the machine.

Downloads

FILLCONTROL FreeViewer is a free software module and enables the recorded data of all FILLCONTROL applications to be clearly displayed and analyzed.

In addition, all process monitoring, open-loop and closed-loop control functions can be displayed using previously recorded data or simulation data in a simulation mode.

FILLCONTROL FreeViewer is ideally suited as a management tool for the planning, optimization and analysis of production.

Downloads

| Application |

|---|

| Process visualization |

| Process analysis |

| Data analysis of all modules |

|

Demo mode and simulation of all functions |

|

Accessories |

|---|

| Windows PC / Laptop |

| BlueLine Core Type 8280C |

FILLCONTROL Measure is a free software module with which measurement data such as cavity pressure, cavity temperature or voltage signals can be easily recorded and stored.

All that is needed is a combined connection cable both to power the amplifiers and to transfer data to the Windows PC/laptop and amplifiers.

Downloads

| Application |

|---|

| Data acquisition |

| Data storage |

| Process visualization |

| Process analysis |

FILLCONTROL Monitor is a comprehensive process monitoring module and serves as the basis for all PRIAMUS® systems. It offers the possibility of simple bad part separation such as the removal of individual bad parts with the help of individual alarm signals

In addition, FILLCONTROL Monitor offers the opportunity of detecting the melt position in the cavity, switching over to holding pressure automatically or via switching level and monitoring viscosities.

The quality-dependent monitoring parameters are divided into warning, intervention and alarm limits.

| Application |

|---|

| Good / bad part separation |

| Switchover to holding pressure via switching level |

| Automatic switchover to holding pressure |

| Viscosity monitoring |

| Application | Problem | Example | Solution |

|---|---|---|---|

| General | Parts are not filled | Cable connector | Monitoring the pressure level |

| Coinjection | Uncontrolled filling | Food container | Monitoring the sheer rate |

| Family molds | Different length of flow paths | Model kits | Monitoring the individual cavities |

Downloads

FILLCONTROL Switch generates real-time switching signals on detection of the melt front and thus enables targeted open-loop process control depending on the flow process.

As soon as the melt in the cavity reaches the position of a cavity pressure sensor or a cavity temperature sensor, a switching signal is generated and used for appropriate switching operations depending on the application.

The switching signals can either be delayed or switched on and off depending on each other.

| Application |

|---|

| Automatic sequential control |

| Valve gate nozzle control |

| Core pull control |

| Automatic venting |

| Rotary table applications |

| Automatic injection compressing molding |

| Application | Problem | Example | Solution |

|---|---|---|---|

| Overmolding of insert parts | Flow mark | Golf balls | Automatic core pull control |

| Sequential molding | Weld lines | Bumper | Automatic valve gate nozzle control |

| Liquid silicon rubber | Unequal compression | Heart catheter |

Downloads

FILLCONTROL Control H is a module for the balancing of hot runner multi-cavity molds and fully automatic control of the melt flow in large-area components.

In this very effective process, the settings of the hot runner nozzles are permanently corrected depending on the respective melt flow in the cavity. This way, unfilled parts in multi-cavity molds are excluded and weld lines in large-area components are specifically controlled, moved and held in position.

This process is the prerequisite for a systematic reduction of cycle times for multiple molds.

| Application |

|---|

| Hot runner balancing |

| Hot runner control |

| Application | Problem | Example | Solution |

|---|---|---|---|

| Multi-cavity molds | Different filling grade | Infusion systems | Automatic hot runner balancing |

| Ceramics injection molding | Dimensional variations | HID lamps | |

| Multi-cavity molds | Cycle time too long | Contact lenses |

Downloads

Due to material variations and different environmental conditions, bad parts are often produced with a constant machine setting.

FILLCONTROL Control P regulates the injection molding process fully automatically by permanently adjusting the machine parameters. This is the only way to ensure that molds can be transferred from one location to another.

In the end, the quality parameters such as compression, viscosity or the dimension of a molded part are directly controlled. A prerequisite for this is the separate measurement of the pressure and the temperature in the cavity.

| Application |

|---|

| Automatic closed-loop process control |

| Application | Problem | Example | Solution |

|---|---|---|---|

| Processing of recycled materials | Viscosity variations | Tractor covers | Viscosity control |

| Precision injection molding | Dimensional variations | Blister packaging | Shrinkage control |

| Technical parts | Insufficient strength | Gear wheels | Compression control |

Downloads

FILLCONTROL Control V balances and controls the melt flow, especially in cold runner molds, by automatically delaying the opening times of the valve gate nozzles.

Similar to hot runner multi-cavity molds, this leads to all cavities being filled at the same time. This is particularly important for silicone and multi-component applications.

This way, unfilled parts in multi-cavity molds are excluded and weld lines in large-area components are specifically controlled, moved and held in position.

In general, it is possible to regulate the opening times of each valve gate nozzle individually, which is effectively used for family molds, for example. The nozzles are opened in real time by detecting the melt front in the cavity, so no host computer interface is required.

| Application |

|---|

| Valve gate nozzle balancing |

| Valve gate nozzle control |

| Application | Problem | Example | Solution |

|---|---|---|---|

| Liquid silicon rubber (LSR) | Different compressions | Overmolded airbag igniters | Automatic balancing and control of valve gate nuzzles |

| Family molds | Different volumes | Food container | |

| Thermoplastic (LSR) | Unsteady volumes | Oxygen masks |

Downloads

FILLCONTROL mobile monitoring system type 7090A-xpxT

Usually FILLCONTROL Monitor is permanently installed on the injection molding machine. The monitoring system type 7090A-xpxT is a mobile version for service, tests and laboratory applications for which all necessary BlueLine components such as connection cables, amplifiers and the BlueLine Core can be stored in a robust transport case.

Downloads

BlueLine Core Type 8280C

The BlueLine Core is a powerful basic device for monitoring, open-loop and closed-loop process control of the injection molding process and serves as a platform for all FILLCONTROL software modules.

The BlueLine Core is equipped with a capacitive touch screen which can be easily operated even under production conditions.

The cleanroom-suitable device has a large number of digital interfaces via which all BlueLine devices are controlled.

A network connection is also possible via the Ethernet interface.

Download

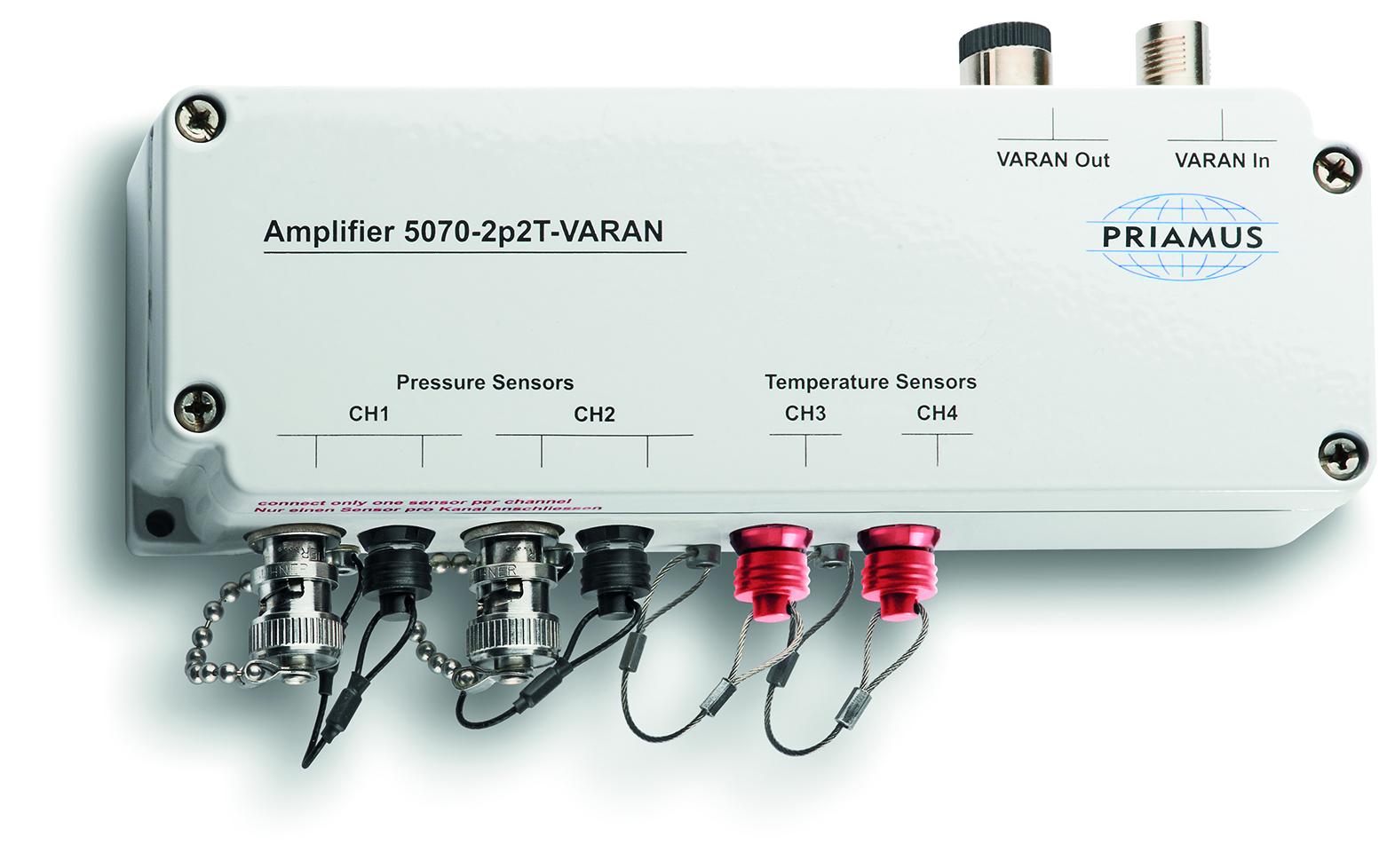

BlueLine Pressure and temperature amplifier type 5070A-2p2T-VARAN

The pressure and temperature amplifier type 5070A-2p2T-VARAN processes two cavity pressure and two cavity temperature signals in a total of four channels.

Connector: 2 × Fischer type 102 TRIAX, 2 × Fischer type 101 TRIAX

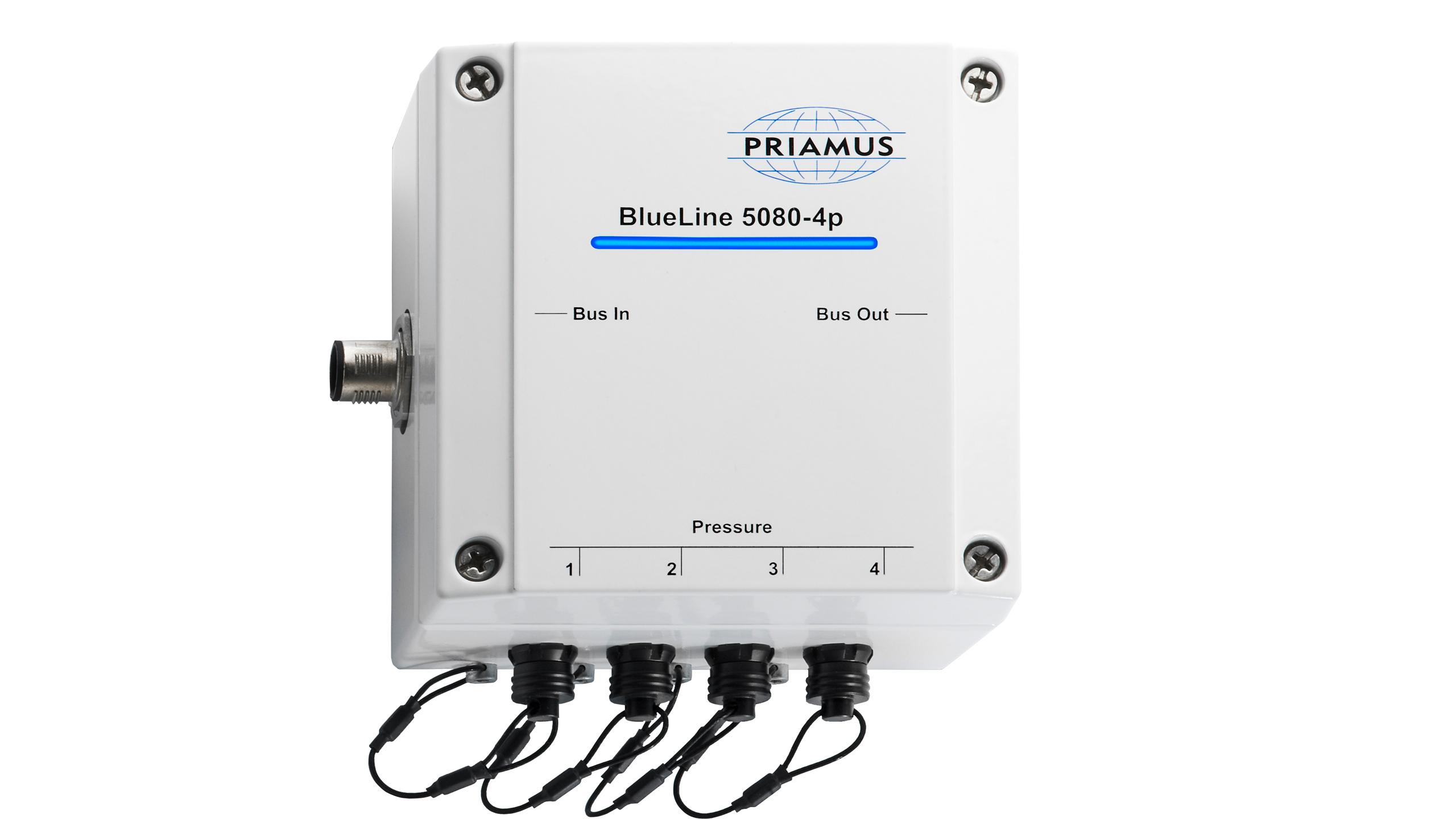

BlueLine pressure amplifier type 5080-4p

The BlueLine cavity pressure amplifier type 5080-4p processes cavity pressure signals on four channels.

Connector: 4 × Fischer type 102 TRIAX

BlueLine pressure amplifier type 5080-16p

The BlueLine cavity pressure amplifier type 5080A-16p processes 16 cavity pressure signals.

Connector: 2 × Fischer type 104, 16-pin

BlueLine temperature amplifier type 5080A-4T

The BlueLine cavity temperature amplifier type 5080A-4T processes four cavity temperature signals.

Connector: 4 × Fischer type 101 TRIAX

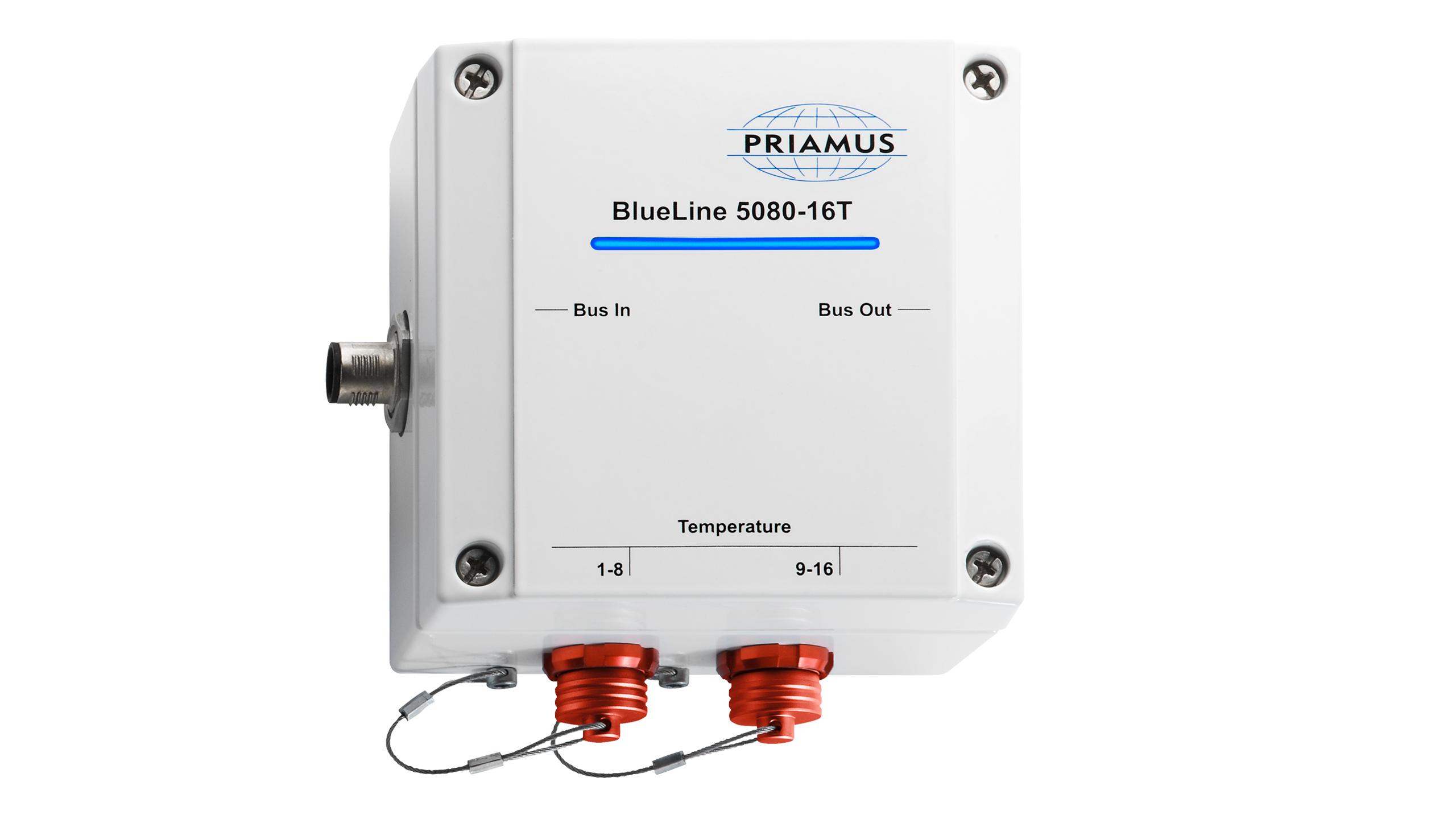

BlueLine temperature amplifier type 5080A-16T

The BlueLine cavity temperature amplifier type 5080A-16T processes 16 cavity temperature signals.

Connector: 2 × Fischer type 106, 19-pin

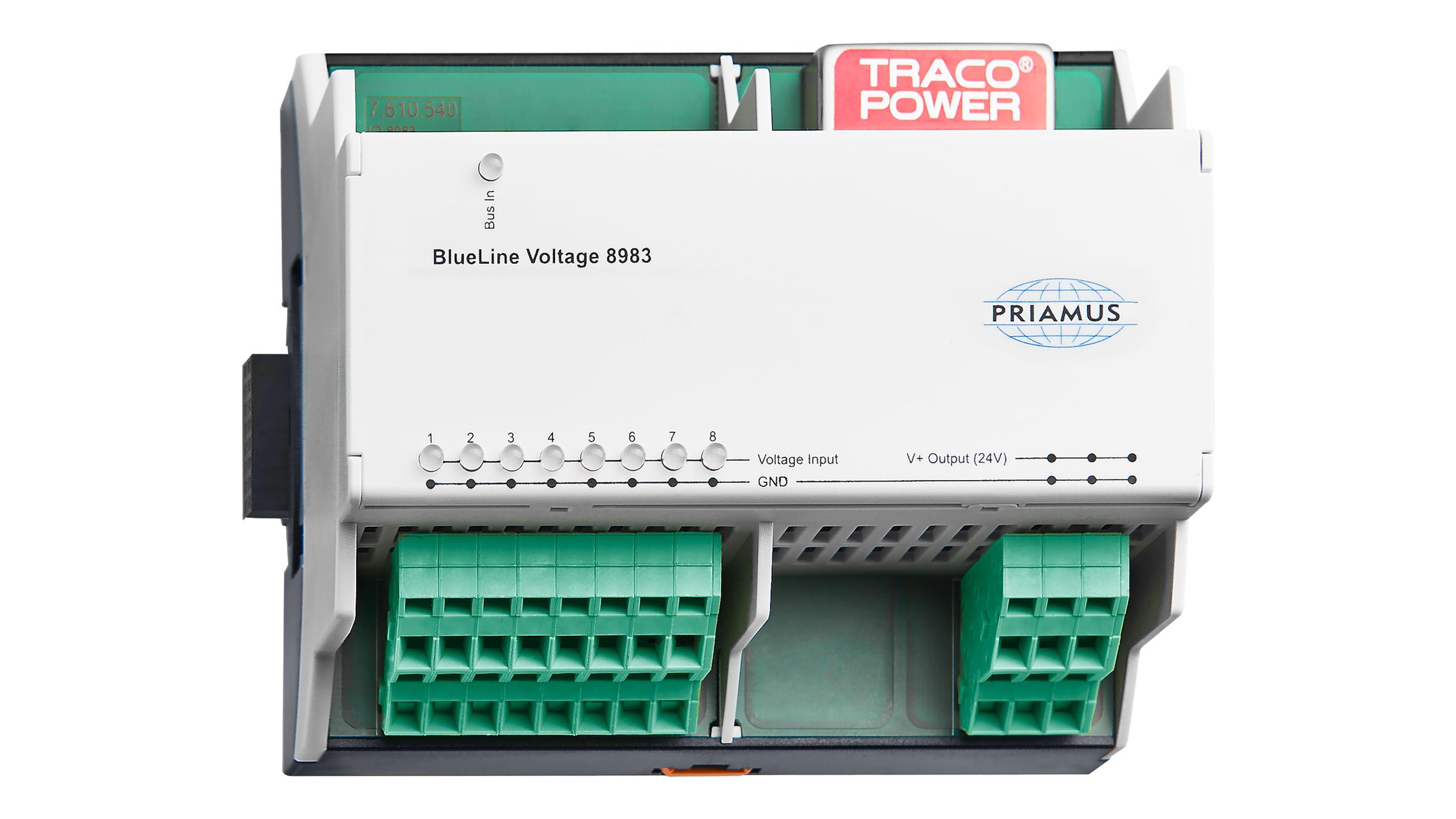

BlueLine Voltage Input Module type 8983A

The BlueLine voltage input module is used for the simple recording of voltage signals as they are usually provided by injection molding machines.

These are usually setpoint and actual signals of the set machine parameters such as hydraulic pressure, screw position or injection speed.

The voltage signals are recorded in the FILLCONTROL software as analog signals and subsequently documented as quality parameters or used for control purposes.

The device is designed for installation in a control cabinet and is coupled to the I/O master via the "Bus In" connection.

Download

BlueLine Machine Interfaces

Important components of a measuring system are the interfaces. Our BlueLine interfaces I/O Master and I/O Expander are easily installed in the control cabinet and connected to the machine controller.

All control signals as well as all warning, intervention and alarm signals for reject separation are transmitted by the control system via a single hybrid bus cable. Our interfaces are modular and can be plugged together on a top-hat rail.

I/O Master Type 8980C

The I/O Master type 8980C is a basic module within the BlueLine system with digital inputs and outputs. Its main task is to transmit control signals between the injection molding machine and the BlueLine system.

All outputs of the I/O Master are short-circuit and overvoltage-proof and also protected against reverse polarity. Thanks to the two-color LEDs, the status of the inputs and outputs can be checked at a glance at any time.

Download

I/O Expander Type 8981A

The I/O Expander type 8981A is an expansion module within the BlueLine system with digital inputs and outputs. Its main task is to transmit control signals between the injection molding machine and the BlueLine system.

All outputs are short-circuit and overvoltage-proof and also protected against reverse polarity. Thanks to the two-color LEDs, the status of the inputs and outputs can be checked at a glance at any time.

Download

Bus Interface Type 8982A

The BlueLine Bus Interface type 8982A is used to connect an I/O module series consisting of an I/O Master and one or more I/O Expanders. The modules are then connected to each other using a separately available hybrid bus cable.

I/O Master and I/O Expander modules are coupled directly, i. e. without cables, on a top hat rail bus. The bus interface is used to connect offset or more distant modules to the hybrid bus cable.

Download

External interfaces types 8980C-E & 8981A-E

External interfaces are available for mounting the BlueLine I/O Master and I/O Expander outside the control cabinet. A single I/O Master or I/O Expander is supplied in external housing with a plug connection. Thanks to the compact design, up to 16 switching signals can be processed.

External interfaces types 8984A & 8985A

The external interface types 8984A and 8985A are control cabinets with visible doors which have been equipped with BlueLine interfaces.

Type 8984A has a BlueLine I/O Master and can be optionally expanded with one to four BlueLine I/O Expanders. Up to a maximum of 64 switching signals (e.g. valve gate nozzles) can therefore be processed.

Type 8985A also has a BlueLine I/O Master but can be optionally expanded with one to six BlueLine I/O expanders. Up to a maximum of 96 switching signals (e.g. valve gate nozzles) can therefore be processed.

Download

BlueLine signal tester

Trust is good - testing is better

In order to obtain error-free measurement results, all components of the BlueLine system must work together without errors at all times. To avoid unpleasant surprises, it is a good idea to check the components from time to time; the best way is to use the BlueLine signal tester type 8952A.

In addition to checking cavity pressure and cavity temperature signals, the BlueLine signal tester can also be used to check other potencial sources of errors such as sensor sensitivity or cable breakage. The preset programs can be selected via a display and are immediately ready for use

The BlueLine signal tester is available as a single device or as a complete set in a case.

BlueLine Signal tester Type 8952A

With the BlueLine signal tester, individual components within the BlueLine system can be specifically checked.

The signal tester is powered by three 1.5V AA batteries and can be expanded with numerous accessories.

BlueLine Signal tester set Type 8911A

The BlueLine signal tester set includes the following components:

1 × signal tester type 8952A

3 × 1.5V AA batteries

1 × test pin type 6902B

1 × short circuit plug for temperature signals type 9017A

1 × short circuit plug for pressure signals type 9018A

1 × connecting cable between signal tester and test pin type 1041A2

1 × case with foam inlet type 9022A

Downloads

BlueLine Multi-channel connector boxes

The thermoelectric voltages of the cavity temperature and charges of the cavity pressure measured in the mold are extremely small measured variables that are susceptible to faults, especially at high mold temperatures.

The quality of the measuring signals depends largely on the connection technology and a safe ground connection to the mold. For this reason, PRIAMUS only uses cable connections with more than one conductor.

Multi-channel connector boxes guarantee a secure ground connection to the mold and can be installed both on the mold surface and integrated into the mold. Depending on the requirements and position of the sensors, the multi-channel connector boxes are installed on the mold.

Multi-channel connector box for cavity temperature signals type 1194A-8T

Download

Multi-channel connector box for cavity pressure signals type 1195-8p

BlueLine-Zubehör

Numerous connecting cables are used to ensure that the components within the BlueLine system can communicate with each other as desired. An overview of the most important connection cables and other useful BlueLine accessories can be found in the following PDF file.

Download

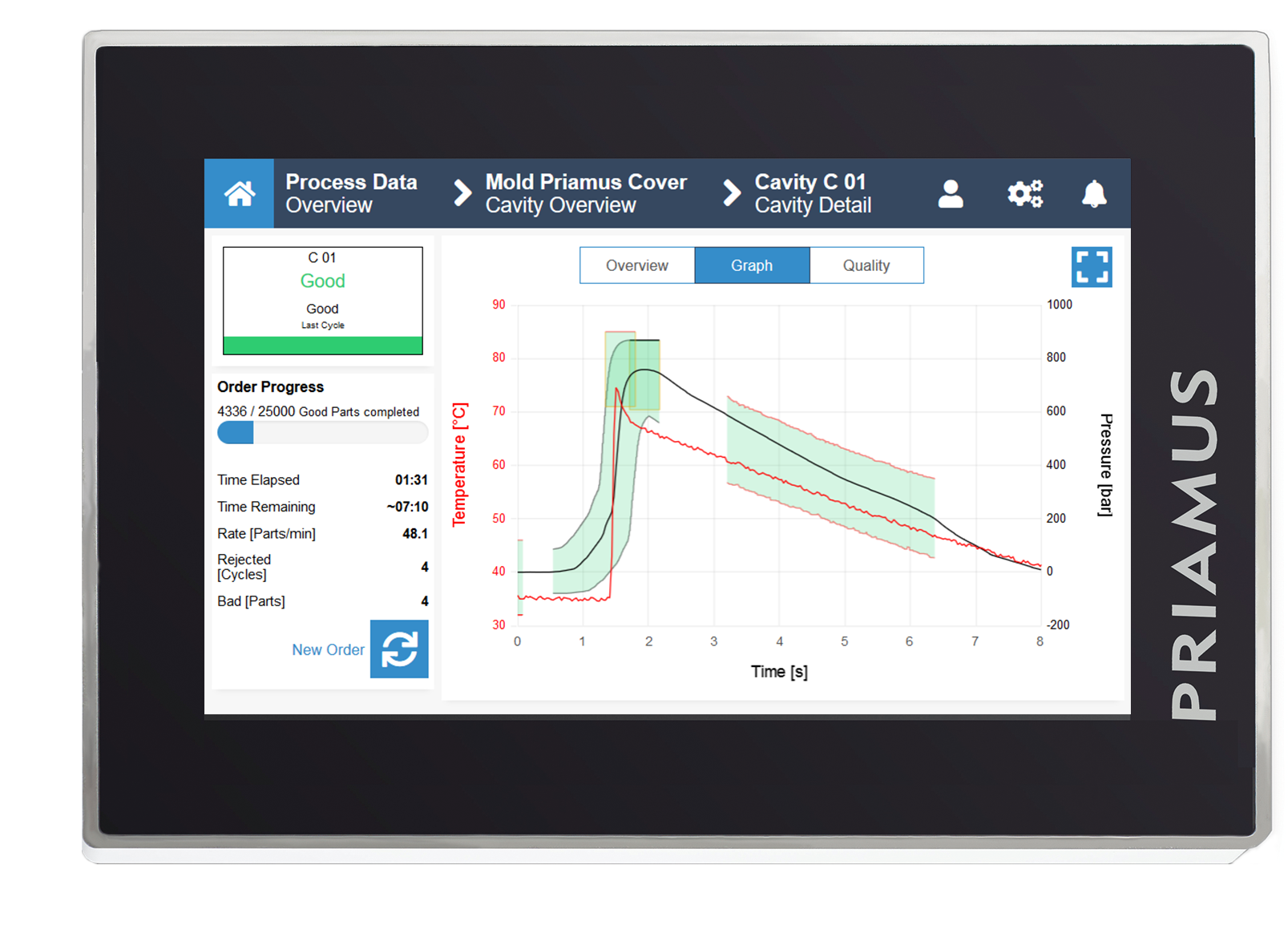

Quality Monitor™ - The overall system for easy process monitoring

Quality Monitor™ is used for simple and reliable monitoring of the industrial injection molding process and is based on real process parameters. The basis for this is the process information obtained from the cavity pressure and cavity temperature sensors.

The central component of Quality Monitor™ is the digital data acquisition unit with integrated monitoring software, which can be operated without a PC. With the integrated OPC-UA interface, Quality Monitor™ is the ideal IoT (Internet of Things) platform.

The system can be operated with any web browser-based screen. Ideally, the system is operated together with the QScreen™ control terminal and the multicolor LED signal lamp.

The system is compatible with all PRIAMUS BlueLine devices and can be supplemented with BlueLine amplifiers and machine interfaces depending on the application.

Download

Quality Monitor™ QScreen® control terminal type 8281A

The Quality Monitor™ QScreen control terminal has a 7-inch capacitive touchscreen and is used for web browser-based control of the digital data acquisition unit.

The control terminal is connected to the digital data acquisition unit via an Ethernet cable. The data transfer to a local server or a cloud takes place via the OPC UA protocol. User-specific information is stored and system updates are performed via the USB interface.

The VESA interface on the back of the housing is used to fix the operating terminal. In addition, magnetic disks are located on the back of the housing, which allow the QScreen control terminal to be positioned anywhere on the machine.

Download

Quality Monitor™ Digital Data Acquisition Unit type 8081A

The digital data acquisition unit is the central system component of Quality Monitor™.

The digital data acquisition unit is preferably controlled with the QScreen® control terminal, but can also be controlled with other browser-compatible devices. The digital data acquisition unit receives and processes all input signals. Depending on the configuration, the processed signals are used for process monitoring and output signals can be controlled.

The data is located on a web interface and can also be output as PDF in a quality report if required.

Download

Multicolor LED signal lamp type 9023A

The multicolor LED signal lamp is directly controlled by the PRIAMUS systems and can be directly connected to the core type 8280C or the QScreen™ control terminal.

It is attached directly to the BlueLine Core with the mounting type 9024A or attached to a desired location on the machine with the magnetic mounting type 9025A.

The signal lamp is controlled as a serial interface via a USB connection and can display more than 200,000 colors (RGB LEDs) and lighting effects.

Download

Sensors

Standard Cavity Pressure Sensors

Type 6001

| Type number | Sensor front | Product properties | |

|

6001Ax.x-102 |

Machinable | - | |

|

6001Ax.x-102-H |

Machinable, hardened | - | |

|

6001Bx.x-102 |

Machinable |

PRIASED® |

|

|

6001Bx.x-102-H |

Machinable, herdened |

PRIASED® |

|

Type 6001B

Sensor with angeled connector

| Type number | Sensor front | Product properties | |

|

6001Bx.x-102-W |

Non-machinable | PRIASED® | |

|

6001Bx.x-102-H-W |

Non-machinable, hardened | PRIASED® | |

Type 6002B

| Type number | Sensor front | Product properties | |

|

6002Bx.x-102 |

Machinable | PRIASED®, PRIASAFE™ | |

|

6002Bx.x-102-H |

Machinable, hardened | PRIASED®, PRIASAFE™ | |

Type 6002B

Sensor with angeled connector

| Type number | Sensor front | Product properties | |

|

6002Bx.x-102-W |

Non-machinable | PRIASED®, PRIASAFE™ | |

|

6002Bx.x-102-H-W |

Non-machinable, hardened |

PRIASED®, PRIASAFE™ |

|

Typ 6003

| Type number | Sensor front | Product properties | |

|

6003Ax.x-102 |

Machinable | - | |

|

6003Ax.x-102-H |

Machinable, hardened | - | |

|

6003Bx.x-102 |

Machinable |

PRIASED® | |

|

6003Bx.x-102-H |

Machinable, hardened |

PRIASED® |

|

Type 6003B

Sensor with angeled connector

| Type number | Sensor front | Product properties | |

|

6003Bx.x-102-W |

Non-machinable | PRIASED® | |

|

6003Bx.x-102-H-W |

Non-machinable, hardened |

PRIASED® |

|

Futher Information and Downloads

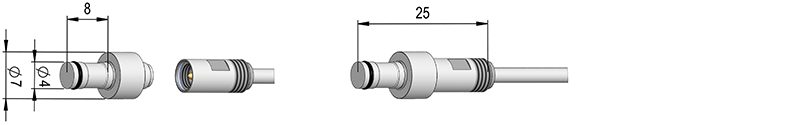

Miniature Cavity Pressure Sensors

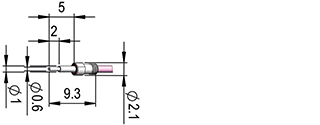

Type 6006BC

| Type number | Sensor front | Product properties | |

|

6006BCx.x-102 |

Machinable |

PRIASED®, PRIASAFE™ |

|

Type 6006BC

Sensor with angled connector

| Type number | Sensor front | Product properties | |

|

6006BCx.x-102-W |

Non-machinable |

PRIASED®, PRIAFIT® |

|

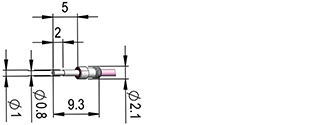

Type 6007BC

| Type number | Sensor front | Product properties | |

|

6007BCx.x-102 |

Non-machinable | PRIASED®, PRIASAFE™ | |

Type 6008AA

| Type number | Sensor front | Product properties | |

|

6008AAx.x-102 |

Machinable | - | |

Type 6010BC

| Type number | Sensor front | Product properties | |

|

6010BCx.x-102 |

Machinable | PRIASED®, PRIASAFE™ | |

Type 6010BC

Sensor with angled connector

| Type number | Sensor front | Product properties | |

|

6010BCx.x-102-W |

Non-machinable | PRIASED®, PRIASAFE™ | |

Further Information and Downloads

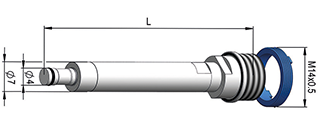

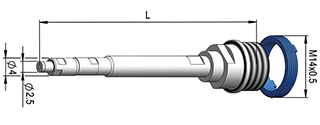

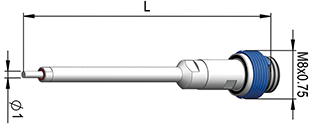

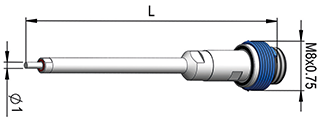

Compact Sensors for Cavity Pressure with Quick Disconnect

Compact Sensors for Cavity PRessure with Quick Disconnect Type A

Type 6001

| Type number | Sensor front | Product properties | Possible length L |

|

6001Axxx.xxA |

Machinable |

- |

44 ... 160 mm |

| 6001Bxxx.xxA | Machinable | PRIASED® | 44 ... 160 mm |

Type 6002B

| Type number | Sensor front | Product properties | Possible length L |

|

6002Bxxx.xxA |

Machinable |

PRIASED®, PRIASAFE™ |

46 ... 160 mm |

Type 6003

| Type number | Sensor front | Product properties | Possible length L |

|

6003Axxx.xxA |

Machinable | - | 44 ... 160 mm |

| 6003Bxxx.xxA | Machinable | PRIASED® | 44 ... 160 mm |

Type 6006BC

| Type number | Sensor front | Product properties | Possible length L |

|

6006BCxxx.xxA |

Machinable |

PRIASED®, PRIASAFE™ |

41 ... 160 mm |

Type 6008AA

| Type number | Sensor front | Product properties | Possible length L |

|

6008AAxxx.xxA |

Machinable | - | 50 ... 160 mm |

Type 6010BC

| Type number | Sensor front | Product properties | Possible length L |

|

6010BCxxx.xxA |

Machinable |

PRIASED®, PRIASAFE™ |

41 ... 160 mm |

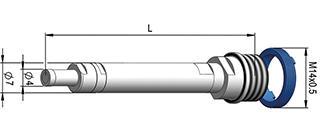

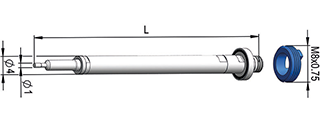

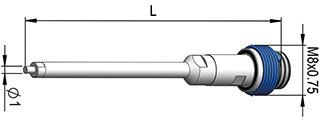

Compact Sensors with Quick Disconnect Type A1

Type 6006BC

| Type number | Sensor front | Product properties | Possible length L |

|

6006BCxxx.xxA1 |

Machinable |

PRIASED®, PRIASAFE™ |

24 ... 160 mm |

Type 6008AA

| Type number | Sensor front | Product properties | Possible length L |

|

6008AAxxx.xxA1 |

Machinable |

- |

33 ... 160 mm |

Type 6010BC

| Type number | Sensor front | Product properties | Possible length L |

|

6010BCxxx.xxA1 |

Machinable |

PRIASED®, PRIASAFE™ |

24 ... 160 mm |

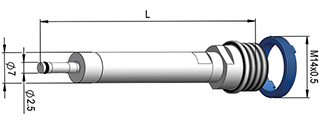

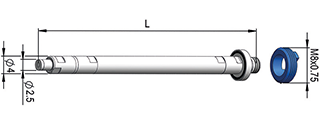

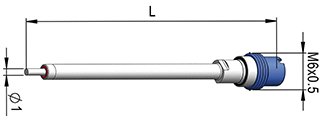

Compact Sensors with Quick Disconnect Type A2

Type 6006BC

| Type number | Sensor front | Product properties | Possible length L |

|

6006BCxxx.xxA2 |

Machinable |

PRIASED®, PRIASAFE™ |

30 ... 160 mm |

Type 6008AA

| Type number | Sensor front | Product properties | Possible length L |

|

6008AAxxx.xxA2 |

Machinable |

- |

39 ... 160 mm |

Type 6010BC

| Type number | Sensor front | Product properties | Possible length L |

|

6010BCxxx.xxA2 |

Machinable |

PRIASED®, PRIASAFE™ |

30 ... 160 mm |

Further Information and Downloads

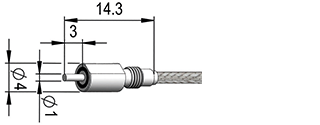

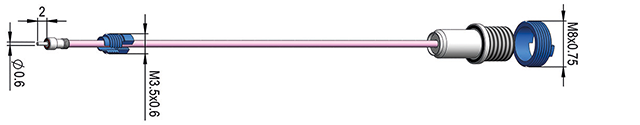

Flexible Quick Disconnects for Cavity Pressure sensors

Flexible quick disconnects for mounting in mold insert

Type 6101

| Type number | Compatible with sensor | Delivered mounting nut | |

|

6101Ex.xx |

Standard cavity pressure sensors |

Types 6541A & 6546A |

|

Type 6103

| Type number | Compatible with sensor | Delivered mounting nut | |

|

6103Ex.xx |

Miniature cavity pressure sensors Types 6006BC, 6007BC, 6010BC |

Types 6544B & 6546A |

|

Type 6104

| Type number | Compatible with sensor | Delivered mounting nut | |

|

6104Bx.xx |

Miniature cavity pressure sensors Type 6008AA |

Types 6544B & 6546A |

|

Type 6106

| Type number | Compatible with sensor | Delivered mounting nut | |

|

6106Ax.xx |

Standard cavity pressure sensors Types 6001A, 6003A |

Types 6541A & 6546A |

|

Quick Disconnect Cable Type 6100

| Type number | Compatible with |

|

6100Ex.x-102 |

All compact sensors for cavity pressure with quick disconnect type A |

Quick Disconnect Cable Type 6102

| Type number | Compatible with |

|

6102Ex.xA1-102 |

All compact sensors for cavity pressure with quick disconnect type A1 |

Flexible quick disconnects for mounting in floating mold insert

Type 6201

| Type number | Compatible with sensor | Delivered mounting nut | |

|

6201Ax.xx |

Standard cavity pressure sensor Types 6001B, 6002B, 6003B |

Types 6541A & 6555A |

|

Type 6203

| Type number | Compatible with sensor | Delivered mounting nut | |

|

6203Ax.xx |

Miniature cavity pressure sensors Types 6006BC, 6007BC, 6010BC |

Types 6544B & 6555A |

|

Type 6204

| Type number | Compatible with sensor | Delivered mounting nut | |

|

6204Ax.xx |

Miniature cavity pressure sensor Type 6008AA |

Types 6544B & 6555A |

|

Quick Disconnect Cable Type 6200

| Type number | Compatible with |

|

6200Ax.x-102 |

All BlueLine sensors All compact sensors with flexible quick disconnect for mounting in floating mold insert |

Further Information and Downloads

PiezoeleCTRIC Force Sensors

| Typennummer | Länge A | Länge B | Länge C | Produkteigenschaften |

|

6411Bx.x-102 |

6 mm | 3.9 mm | 6 mm | - |

|

6413Ax.x-102 |

12 mm | 4.1 mm | 3 mm | - |

|

6414Ax.x-102 |

20 mm | 8.1 mm | 3.5 mm | - |

|

6415Ax.x-102 |

30 mm | 12.1 mm | 4 mm | - |

Further Informations and Downloads

Cables for Cavity Pressure Sensors

Connection cables

With Fischer connector type 102 negative TRIAX

Type 1002Dx.x

| Compatible with all standard cavity pressure sensors types 6001A and 6003A |

Type 1006Cx.x

| Compatible with all piezoelectric force sensors type 6411B |

Type 1009Bx.x

| Compatible with all standard cavity pressure sensors types 6001B, 6002B, 6003B |

Type 1010Cx.x

| Compatible mit all miniature cavity pressure sensors types 6006BC, 6007BC, 6010BC |

Type 1011Ax.x

| Compatible with all miniature cavity pressure sensors type 6008AA |

Type 1019Ax.x

| Compatible with all standard cavity pressure sensors with angled connectors types 6001B, 6002B, 6003B |

Type 1020Ax.x

| Compatible with all miniature cavity pressure sensors with angled connectors types 6006BC, 6010BC |

Connection cables single-channel

With Fischer connector type S 102 positive TRIAX

Type 1041A

|

Coat material: plastic Compatible with all cavity pressure sensors |

Type 1049Bx

|

Coat material: metal Compatible with all cavity pressure sensors |

Connection cables multi-pin

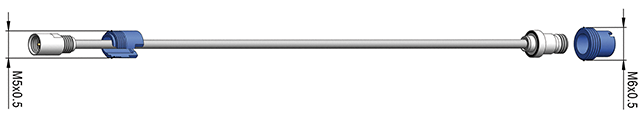

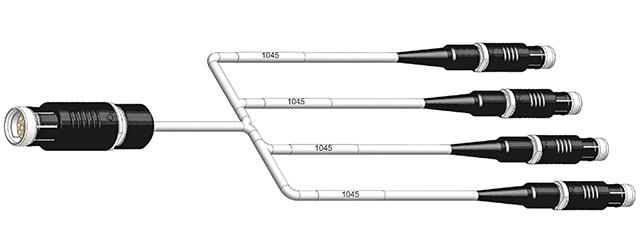

Type 1045Bx

|

Coat material: plastic Connector: Compatible with all cavity pressure sensors |

Type 1047Ax

|

Coat material: plastic Connector: Compatible with all cavity pressure sensors |

Type 1054Bx

|

Coat material: plastic Connector: both sides Fischer type S 104 neg. 16-pin (Code 1) Compatible with all cavity pressure sensors |

Extension cables

Type 1043Bx

|

Coat material: metal Connector: Compatible with all cavity pressure sensors |

Standard Cavity temperature Sensors

TypE 4004

| Type number | Sensor front | ||

|

4004Dx.x-101 |

Unmachinable |

|

|

| 4004Cx.x-101-H | Unmachinable, hardened | ||

TypE 4006

| Type number | Sensor front |

|

4006Cx.x-101 |

Machinable |

| 4006Cx.x-101-H | Machinable, hardened |

TypE 4008

| Type number | Sensor front |

|

4008Cx.x-101 |

Unmachinable |

| 4008Cx.x-101-H | Unmachinable, hardened |

TypE 4010C

| Type number | Sensor front |

|

4010Cx.x-101 |

Unmachinable |

TypE 4012C

Sensor with stepped front diameter

| Type number | Sensor front |

|

4012Cx.x-101 |

Unmachinable |

TypE 4016A

| Type number | Sensor front |

|

4016Ax.x-101-H |

Unmachinable, hardened |

TypE 4018A

Sensor with stepped front diameter

| Type number | Sensor front |

|

4018Ax.x-101-H |

Unmachinable, hardened |

Further Information and Downloads

Heavy-Duty Cavity Temperature Sensors

Type 4030

| Type number | Sensor front | ||

|

4030Bx.x-101 |

Unmachinable |

|

|

| 4030Ax.x-101-H | Unmachinable, hardened | ||

Type 4032

| Type number | Sensor front | ||

|

4032Bx.x-101 |

Machinable |

|

|

| 4032Ax.x-101-H | Machinable, hardened | ||

Type 4034

| Type number | Sensor front | ||

|

4034Bx.x-101 |

Unmachinable |

|

|

| 4034Ax.x-101-H | Unmachinable, hardened | ||

Type 4036

Sensor for indirect measurement

| Type number | Sensor front | ||

|

4036Bx.x-101 |

Unmachinable |

|

|

Further Information and Downloads

Melt Temperature Sensors

Type 4050

| Type number | Sensor front | ||

|

4050Ax.x-101-H |

Machinable, hardened |

|

|

Further Information and Downloads

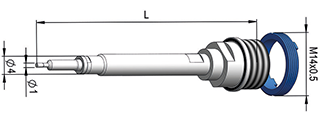

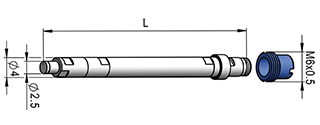

Compact Sensors for Cavity Temperature

With quick disconnect type A1 for mounting in mold insert

Type 4005

| Type number | Sensor front | Possible length L | |

|

4005Cxxx.xxA1 |

machinable |

23.5 ... 120 mm |

|

| 4005Bxxx.xxA1-H | machinable, hardened | 23.5 ... 120 mm | |

TypE 4007

| Type number | Sensor front | Possible length L |

|

4007Cxxx.xxA1 |

unmachinable | 23.5 ... 120 mm |

| 4007Bxxx.xxA1-H | unmachinable, hardened | 23.5 ... 120 mm |

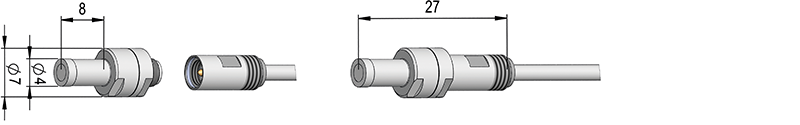

TypE 4009B

| Type number | Sensor front | Possible length L | |

|

4009Bxxx.xxA1 |

unmachinable |

24 ... 120 mm |

|

TypE 4011B

Sensor with stepped front diameter

| Type number | Sensor front | Possible length L | |

|

4011Bxxx.xxA1 |

unmachinable |

27 ... 120 mm |

|

Type 4013A Prisolaris™

Sensor for indirect measurement

| Type number | Sensor front | Possible length L | |

|

4013Axxx.xxA1 |

unmachinable |

22 ... 120 mm |

|

TypE 4015A

| Type number | Sensor front | Possible length L | |

|

4015Axxx.xxA1-H |

unmachinable, hardened |

24 ... 120 mm |

|

TypE 4017A

Sensor with stepped front diameter

| Type number | Sensor front | Possible length L | |

|

4017Axxx.xxA1-H |

unmachinable, hardened |

27 ... 120 mm |

|

With Quick Disconnect Type A2 for Mounting in Floating Mold Insert

Type 4005C

| Type number | Sensor front | Possible length L | |

|

4005Cxxx.xxA2 |

machinable |

18.5 ... 120 mm |

|

TypE 4007C

| Type number | Sensor front | Possible length L | |

|

4007Cxxx.xxA2 |

unmachinable |

18 ... 120 mm |

|

TypE 4009B

| Type number | Sensor front | Possible length L | |

|

4009Bxxx.xxA1 |

unmachinable |

24 ... 120 mm |

|

TypE 4011B

Sensor with stepped front diameter

| Type number | Sensor front | Possible length L | |

|

4011Bxxx.xxA2 |

unmachinable |

20 ... 120 mm |

|

Further Information and Downloads

Miniature Cavity Temperature Sensors with flexible Quick Disconnect

Types for mounting into mold insert

TypE 4103

| Type number | Sensor front | With sensor |

|

4103Fx.xx |

Unmachinable |

Type 4003D |

| 4103Ex.xx-H | Unmachinable, hardened | Type 4003C-H |

TypE 4105

| Type number | Sensor front | With sensor |

|

4105Ex.xx |

Machinable |

Type 4005C |

| 4105Dx.xx-H | Machinable, hardened | Type 4005B-H |

TypE 4107

| Type number | Sensor front | With sensor |

|

4107Ex.xx |

Unmachinable |

Type 4007C |

| 4107Dx.xx-H | Unmachinable, hardened | Type 4007B-H |

TypE 4109C

| Type number | Sensor front | With sensor |

|

4109Cx.xx |

Unmachinable |

Type 4009B |

TypE 4111D

| Type number | Sensor front | With sensor |

|

4111Dx.xx |

Unmachinable |

Type 4011B |

TypE 4115B

| Type number | Sensor front | With sensor |

|

4115Bx.xx-H |

Unmachinable, hardened |

Type 4015A-H |

TypE 4117B

| Type number | Sensor front | With sensor |

|

4117Bx.xx-H |

Unmachinable, hardened |

Type 4017A-H |

Quick Disconnect Cable Type 4100D

| Type number | Compatible with |

|

4100Dx.xA2-101 |

All compact sensors for cavity temperature with quick disconnect type A1 |

Types for mounting into Floating mold plate

TypE 4203A

| Type number | Sensor front | With sensor |

|

4203Ax.xx |

Unmachinable |

Type 4003D |

| 4203Ax.xx-H | Unmachinable, hardened | Typ 4003C-H |

TypE 4205

| Typen number | Sensor front | With sensor |

|

4205Ax.xx |

Machinable |

Type 4005C |

| 4205Ax.xx-H | Machinable, hardened | Type 4005B-H |

TypE 4207A

| Type number | Sensor front | With sensor |

|

4207Ax.xx |

Unmachinable |

Type 4007C |

| 4207Ax.xx-H | Unmachinable, hardened | Type 4007B-H |

TypE 4209A

| Type number | Sensor front | With sensor |

|

4209Ax.xx |

Unmachinable |

Type 4009B |

TypE 4211A

| Type number | Sensor front | With sensors |

|

4211Ax.xx |

Unmachinable |

Type 4011B |

TypE 4215A

| Type number | Sensor front | With sensor |

|

4215Ax.xx-H |

Unmachinable, hardened |

Type 4015A-H |

TypE 4217A

| Type number | Sensor front | With sensor |

|

4217Ax.xx-H |

Unmachinable, hardened |

Type 4017A-H |

Quick Disconnect Cable Type 4200A

| Type number | Compatible with |

|

4200Ax.x-101 |

All compact sensors for cavity temperature sensors with |

Further Information And Downloads

Cables for Cavity Temperature Sensors

Connecting Cables single-channel

With Fischer connector type S 101 positive TRIAX

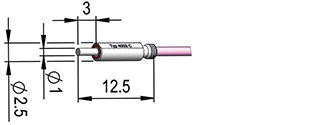

Type 1141A

|

Coat material: plastic Compatible with all cavity temperature sensors |

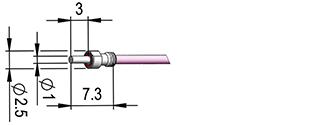

Type 1149Bx

|

Coat material: metal Compatible with all cavity temperature sensors |

Connection cable multi-pin

Type 1144Ax

|

Coat material: plastic Connector: Compatible with all cavity temperature sensors |

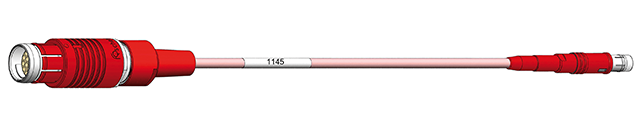

Type 1145Ax

|

Coat material: plastic Connector: Compatible with all cavity temperature sensors |

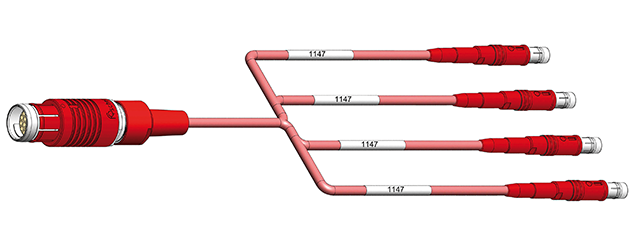

Type 1147Bx

|

Coat material: plastic Connector: Compatible with all cavity temperature sensors |

Extension cables

Type 1142Bx

|

Coat material: metal Connector: Compatible with all cavity temperature sensors |